The marking technologies we use are diverse and complementary so as to be able to offer you a range of options that will correspond to your expectations, whether you are looking for recessed or surface marking that is permanent or one-off. We therefore have a series of managed solutions to create your marking products which make up our standard products. And for any other enquiry, we can determine a specific production process and offer to do you a prototype.

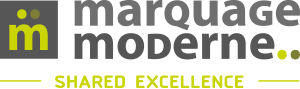

- laser engraving

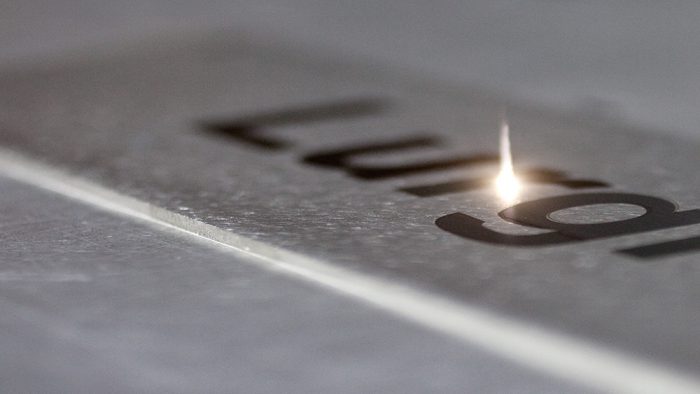

- mechanical engraving

- chemical etching

- screen printing

- digital printing

- embossing

The finish, in other words the final touch given to plates or labels, requires various marking processes to enhance your product. Each finishing phase is carried out to fit the material and the marking chosen. The processes used for these finishing operations take into account the quantity and the final finish required in order to satisfy your needs.

- straight, rounded or customised cut

- machining, bending, milling, chamfering, crimping, riveting, etc.

- protection by varnish or lamination

- mounting by drilling holes or applying adhesive backing

Thanks to their extensive expertise, our sales advisors will determine the best marking solutions so as to achieve the desired result for your plates and labels, whether this be in terms of resistance for the needs of industrial marking or appearance for advertising or communication projects.

We can also offer to supply installation accessories for a turnkey service.